Behind the Build - MDS

- Sales Team

- Canonbury

- 19 Jun 2023

Take a closer look ‘Behind the Build’ inside MDS Medicals UK based manufacturing facility in Corby to discover how MDS Medical’s dedicated team of engineers create quality Autoclaves built to last.

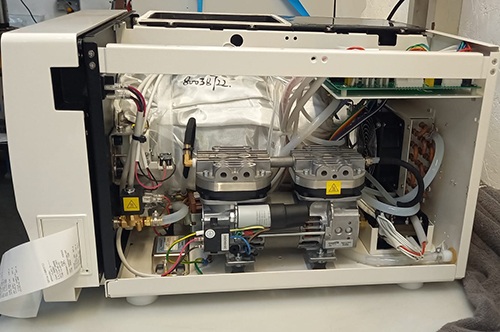

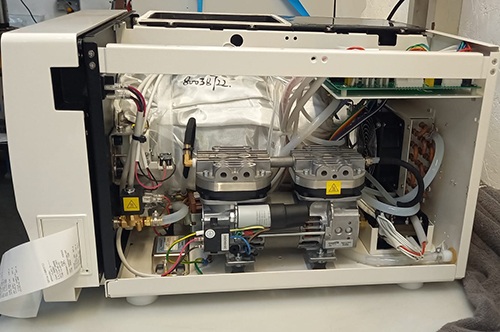

1. Machine build

The first stage of the build process involves manufacturing individual components and fitting them into the casing of the machine. This includes a welded chamber, all electronic components and various types of valves which include water, air & electronic valves.

2. Add Components

Once the first stage of the fitting process is complete, a German designed vacuum pump is added to the machine to ensure both reliability and durability.

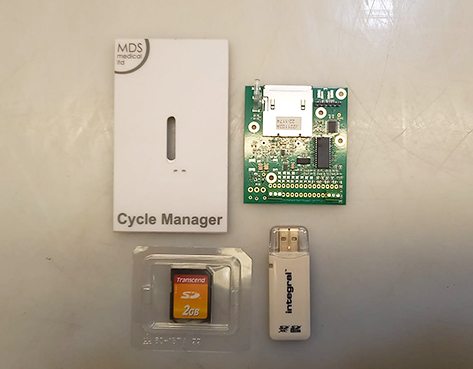

3. Customisation

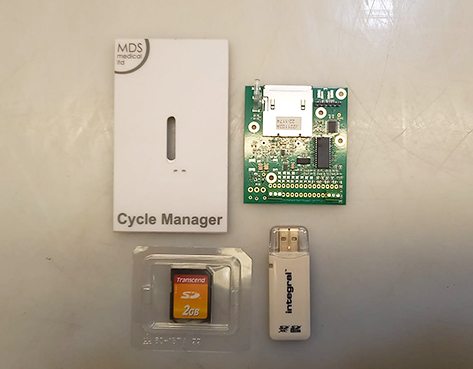

MDS Medical also offer additional features above and beyond the standard autoclave, which can be added at the time of build. These include a data management system or an automatic fill/drain functionality.

4. Quality Control

The final stage of the build process involves comprehensive checks on all wiring, leaks, connections & pipework. The machine is also run on a Vacuum test cycle to ensure its fit for purpose.

5. Delivery

After the build process is complete, the machine is ready for dispatch and loaded onto the vehicle ready for delivery. MDS Medical also offer an engineer delivery & installation service, helping you get started as quickly and easily as possible.

Established in Corby, Northamptonshire in 2010, MDS Medical are a family owned manufacturer of a wide range of autoclave and decontamination equipment, represented exclusively by Canonbury since 2020.

Designed and engineered in the UK, all MDS equipment is manufactured to the highest quality standard and is supplied complete with comprehensive warranties and servicing options for additional peace of mind.

Explore the Range